When Do You Need a Foam Fire Protection System?

Special hazard fire suppression systems can provide highly effective and reliable protection when water-based systems are just not enough. Whether it be highly flammable materials, data centers, pharmaceutical, industrial, commercial, military, or protection of priceless commodities, a special hazard fire protection system may be the right solution to protect your assets. These systems require precision, specialized understanding, and careful engineering to meet industry standards and perform properly when needed most.

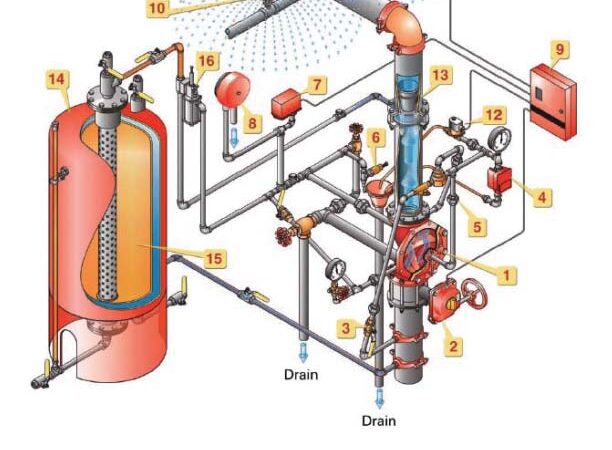

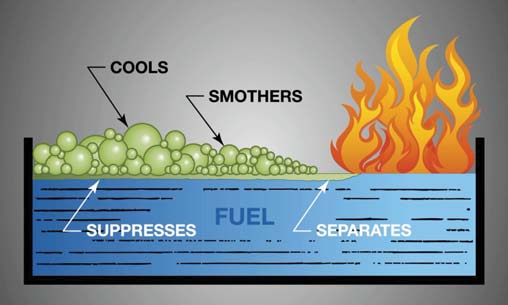

Foam systems are specifically engineered and designed to protect areas where flammable and combustible liquids are present and where traditional water-based systems are not adequate. At the basic level, the foam system consists of a bladder tank, proportioner, and a foam concentrate that when mixed with water and air, produces a foam that is less dense than the liquid it serves to protect. When the foam is introduced to water soluble fuel, it forms a polymeric membrane, which creates a blanket that will separate the fuel from oxygen at the surface level and assist in smothering the fire while creating a barrier to the vapors. Foam systems fall into three categories: Low Expansion, Medium Expansion, and High Expansion foams.

Types of Fire Suppression Foam

There are different types of fire suppression foam for use in different situations. Low expansion foam expands up to 20 times its liquid size and has a good flowability rate for long distance use. This foam’s strong adhesion properties and density make it the least susceptible to being affected by high wind conditions, so it is highly effective in outdoor locations such as helipads and ships. It is able to wet down solid surfaces while still protecting as it creates a dense foam layer that has cooling properties as well as the ability to suppress vapors.

Medium expansion foam will expand from 20 to 200 times its liquid size. With most of the same properties as low expansion foam, medium expansion foam can build up a larger blanket than low expansion foam. However, it is less dense, making it more susceptible to high wind conditions in an outdoor application.

High expansion foam has an expansion rate that is greater than 200 times its liquid form and is generated with more air infusion and less water. Large bubbles build quickly forming a deep layer of fire-fighting foam. These applications are solely used indoors in aircraft hangers, warehouses, or contained rooms as they are very susceptible to windy conditions.

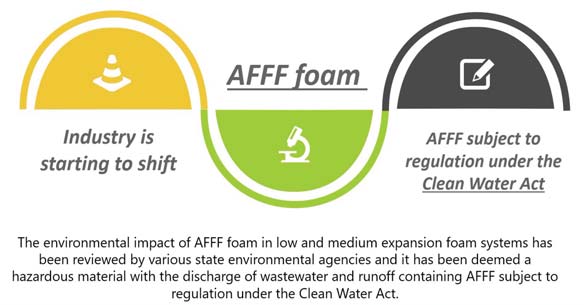

AFFF Foam

The industry is beginning to shift in regards to the use of AFFF foam in foam systems due to their use of PFAS, which include flourosurfactants. On a state by state basis, the sale and use of AFFF is becoming restricted in its usage and/or prohibited from purchase. It will not be long before all of the older C8 long chain foam systems must be replaced with fluorine-free foams. It may not be as simple as a 1 for 1 exchange of these chemicals in your existing foam systems and may require a complete replacement of tanks, proportioners, and other related equipment.

Source: https://oliverfps.com/special-hazard-fire-suppression-systems/