Fire Sprinkler Systems

Our Fire Sprinkler Design & Installation Process

Our design team prepares fire sprinkler installations with 2D or 3D renderings of a space to identify and avoid potential complications. From there, installation is customized to meet your facility’s needs, ensuring all trades are aligned on the best approach. This extra measure of detail ensures we meet all fire codes, insurance requirements, and building-specific needs.

Inspection, Testing, and Maintenance Services

We provide 24/7 emergency service to all of our customers within a two-hour drive of our locations. Additionally, we perform regular inspection, testing, and maintenance services to ensure systems are in good working order and ready to respond in the event of a fire.

We perform physical checks on all fire sprinkler system components to confirm proper function. We also conduct the following tests:

- Main drain tests

- Water flow tests

- Backflow tests

- Fire pump tests

- Corrosion and obstruction tests

- Trip tests for dry pipe, pre-action, and deluge valves

Ensure your system is fully operational and ready to respond to a fire emergency.

Request a quote from our team.

Corrosion Management

Pipe corrosion is a common cause of fire sprinkler system malfunction and failure. Our team is experienced in detecting and resolving this issue before it becomes a dangerous and expensive problem. We have expertise in designing and installing nitrogen based systems that prevent corrosion.

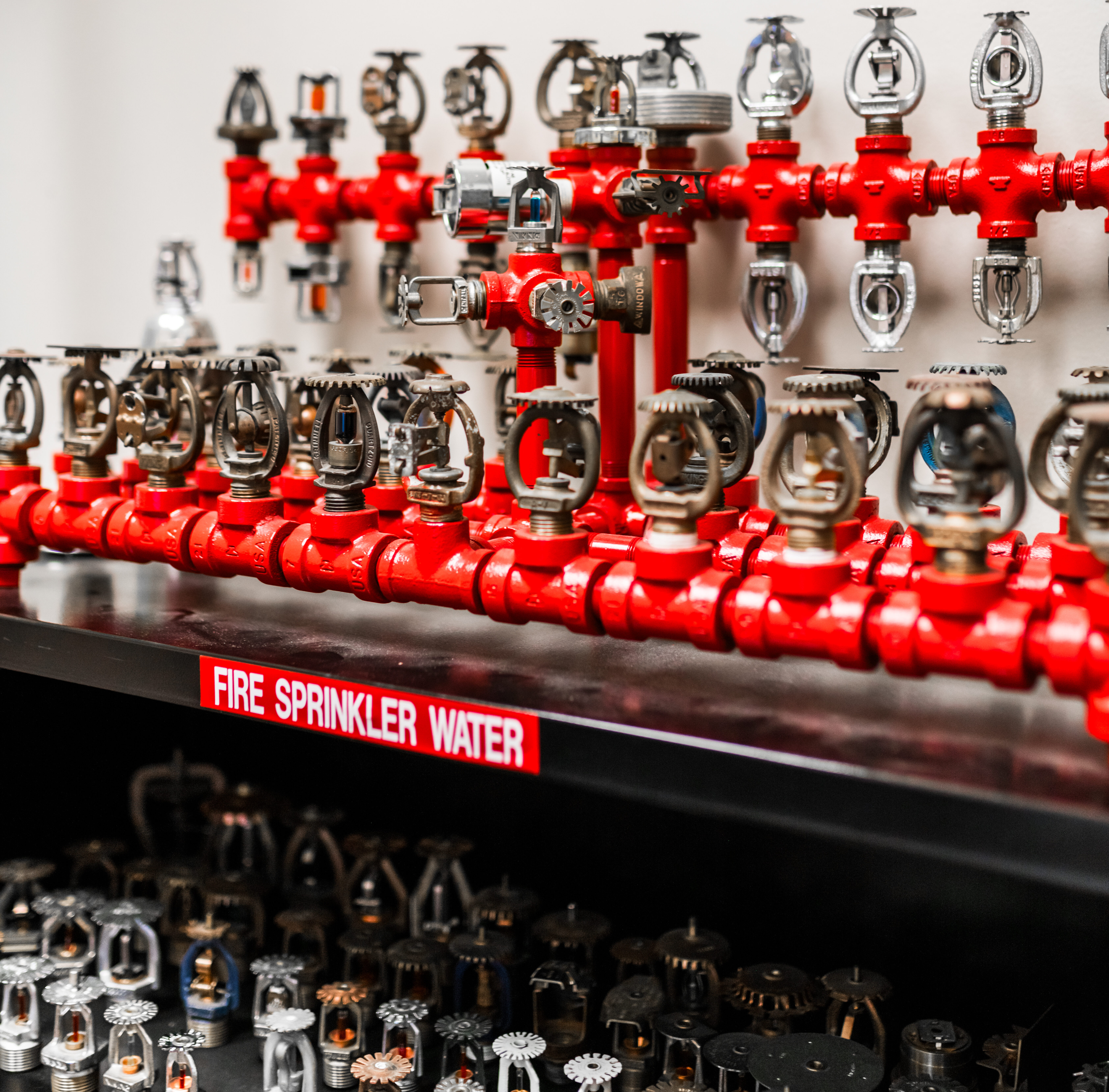

Which Fire Sprinkler System Is Best for Your Facility?

There are many types of fire sprinkler systems on the market, all with their unique advantages and disadvantages. We trust the following systems to be the most effective, but the one that is best for your facility depends on your unique application.

Wet System

- Continuously filled with water

- Can only be used in environments consistently above 40°F

- Suitable for most facilities

Dry System

- Filled with pressurized air, rather than water

- Commonly installed where freezing conditions exist (e.g. attics, loading docks, commercial freezers)

Pre-Action System

- Similar to a dry system, but with an electrically-operated valve that controls water in the piping system

- Commonly installed where sensitive, high-value content is stored (e.g. computer rooms, MRI rooms, art museums)

FM-200/FE 25 System

- Waterless, clean agent fire suppression system

- Environmentally safe and non-toxic to humans

- Leaves no residue upon discharge and requires no cleanup

Learn more and compare the most common types of fire sprinkler systems

Featured Projects

Protect. Prevent. Preserve.

Get Best-in-Class Fire Protection Solutions from Our Experts

Our team is here for you, whenever you need it. Whether you have an emergency request or you’re looking for a quote to outfit your facility, let us know how we can help.

STAY CONNECTED

We’ll let you know of any News, Special Offers, and Training Opportunities